Fix-Mounted ID Readers ID-600

For advanced code-reading tasks in smart production

Fix-Mounted ID Readers ID-600

For advanced code-reading tasks

in smart production

Our ID-600 offers outstanding versatility for the highest degree of productivity in versatile production systems.

The compact, versatile ID readers of the ID-600 series convince with an upgradeable software scope, a clever and robust illumination concept, M12 interchangeable optics as well as extensive optics accessories.

Industry-leading algorithms for high read rates

The ID-600's software-integrated image correction and calibration to optimize image quality guarantees excellent images in terms of distance, field of view and resolution.

With the quickly configurable nVision-i software and the comprehensive code reading tools, optimum performance is achieved with smooth startup and changing requirements. If required, the tools can be extended by a software upgrade or individually optimized by customizing.

The versatile Profinet connection to the existing PLC module and image transfer via FTP/SFTP round off its flexibility.

Your benefits

in detail

Comprehensive focal lengths

through M12 interchangeable lenses

for satisfying all common application requirements in industrial code reading

Integrated high power LED illumination

in red and white, switchable via software

for optimal startup at a high speed and at a large working distance.

User-friendly, intuitive software and high-performance ID code reader tools

ensure simple and seamless integration

Reliable and fast

The ID reader for all common 1D and 2D code types

Upgrade function

License upgrade for reading hard-to-read directly marked codes (DPM)

Customizing

The software can be customized as needed

- Reliable and fast ID reader for all common 1D and 2D code types

- Comprehensive focal lengths through M12 interchangeable lenses

- Integrated high power LED illumination in red and white

- User-friendly, intuitive software and high-performance ID code reader tools

- Image correction and calibration

- License upgrade for reading hard-to-read directly marked codes (DPM)

- Supports industry protocols

- Robust, compact housing with IP67

Robust, compact housing with IP67

for use in factory environments with active washing without attaching additional protective equipment

Supports industry protocols

Digital I/O, TCP/IP, Profinet, HTTP, FTP/SFTP and ReST-API

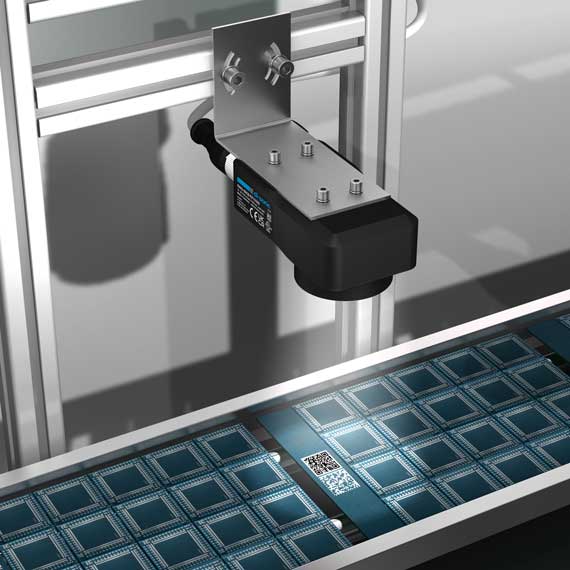

Applications

Our ID-600 units rise to the challenge of even ambitious ambient conditions and code-reading tasks and thus can be used in a variety of industries.

Comprehensive code reading tools ensure that all common 1D and 2D codes are read in, as well as DPM codes and that the determined data and created images are transmitted via various communication interfaces.

Fields of application

- When tracking components, where also directly marked codes are used and not only the decoded data but also the created images have to be transferred (via FTP/SFTP) for quality control of the codes

- In areas where versatility and configurability are required for fast changeovers

Code reading

- in part feeding, assembly and handling technology, secondary packaging etc.

- of very small codes / codes with little contrast

- under demanding lighting conditions

- in plant environments with frequent wash cycles

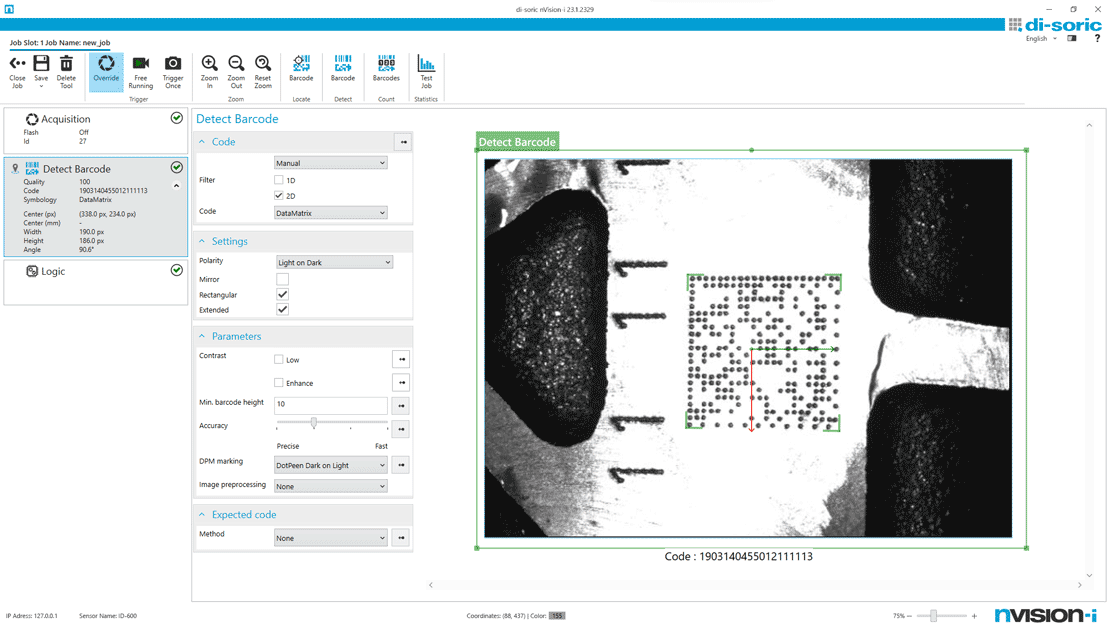

nVision-i

The configuration software

of our ID-600 ID readers

Save time

Not just because of the interface, which is clear, intuitive and simple to operate, but also because of the high-performance tools, which are consistently optimized at the highest quality and with the highest level of performance.

The visualization of the pipeline and linking of individual tasks in the Logic tool make the greatest degree of versatility and high speed in the realization of the application possible.

Pipeline & status checks

- Inspection tools can be inserted here and moved via drag & drop

- Measured values and check results/status are shown here

Navigation bar & inspection tools

- Intuitive and user-friendly navigation menu

- Contextual help can be displayed as needed

- Menu guidance can be toggled between 7 languages (German, English,French, Italian, Spanish, Chinese, and Korean)

Configuration

- Parameters for search criteria can be set simply and directly

- Threshold values for the evaluation criteria can be entered easily

Display & drawing tools

- Image viewing for the control and analysis during operation

- Context-sensitive description of the tools on the right side to ensure optimal tool use with their complete functionality

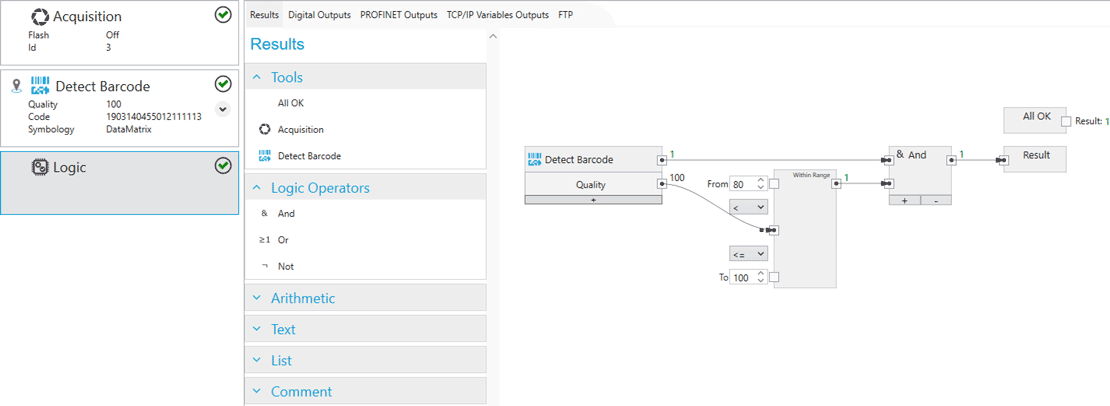

nVision-i

The Logic-Tool

High performance and versatility

The versatility to link various tool results enables the ID reader to process various types without switching between jobs – for example, when the production process runs with multiple varieties.

The great versatility is another advantage.

Profinet communication can be adapted to existing standard communication modules.

Short orientation period, no training required

The graphics-oriented Logic tool is based on a function plan (FUP), whereby a clear display is possible, even in more complex functions. This, in turn, ensures that the implementation of the behavior of inputs and outputs is simple and highly transparent.

This eliminates the need for training, since the procedure is already familiar from daily use of PLC programming.

nVision-i

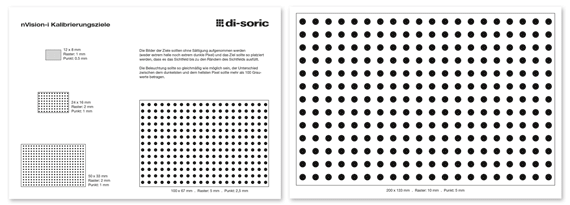

Image correction and calibration

Integrated image optimization

With 2 clicks, distortions and shadowing to the image edge can be easily eliminated by calibration via nVision-i. Thus, the ID reader meets the requirements especially in those areas where flexibility, easy configurability and fast changeovers are in the foreground.

Calibration targets on request

di-soric nVision-i calibration targets can be requested from our support or your account manager.

Select what you need

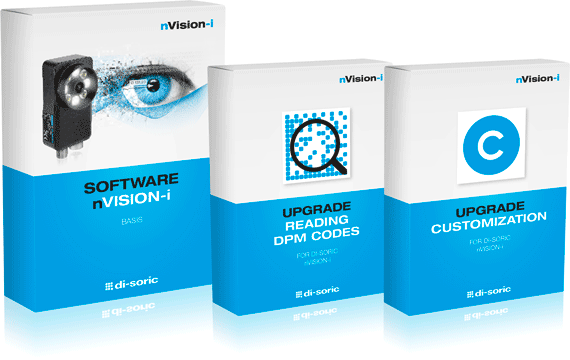

nVision-i is an intuitive and easy-to-use configuration software that can be upgraded and customized to meet your application requirements.

Software nVision-i

Basic license

The free basic license is required to activate the nVision-i software, which you can download from the download area on the detail page of an ID-600.

Upgrade

Module DPM

The ID600-UP-DPM-LIZENZ extends the ID reader with the functions for high-performance reading of hard-to-read directly marked codes (DPM) even on difficult surfaces.

Upgrade

Customization

If necessary, the software can be individually adapted to your requirements. Arrange a consultation appointment with our specialists:

More information

and accessories